Let me ask you something: has your floor scrubber or sweeper suddenly stopped mid-shift, just when your team needed it most?

I’ve been there.

Running a cleaning equipment business, I’ve seen this happen more than I’d like. And the culprit? Battery health—or more often, battery neglect.

If you’re using floor cleaning machines like scrubbers, sweepers, or ride-on units, the battery is your heartbeat. It powers every clean, every shift, and every square meter you’re responsible for. But if the battery’s not healthy, the machine might as well be parked.

This guide will help you understand, test, and take care of your battery, so you get maximum uptime, fewer breakdowns, and longer battery life. It’s everything I wish someone had shown me years ago.

Let’s get into it.

🔋 Why Battery Health Testing Really Matters

A battery might still “work,” but that doesn’t mean it’s healthy.

Without regular checks, you might be running on a half-functional battery that’s damaging your machine, losing power too fast, or failing right when you’re on the job. That’s not just inconvenient — it’s expensive.

So how can you tell if your battery is in good condition or silently dying?

This guide gives you a practical, hands-on approach to battery health testing and maintenance, whether you’re using AGM, gel, or lithium batteries in your cleaning machines.

🔎 1. Know Your Battery: Types & Basics

Before you run a test, you need to understand what kind of battery you’re working with. Trust me, not all batteries behave the same.

🔌 Common Battery Types in Cleaning Equipment:

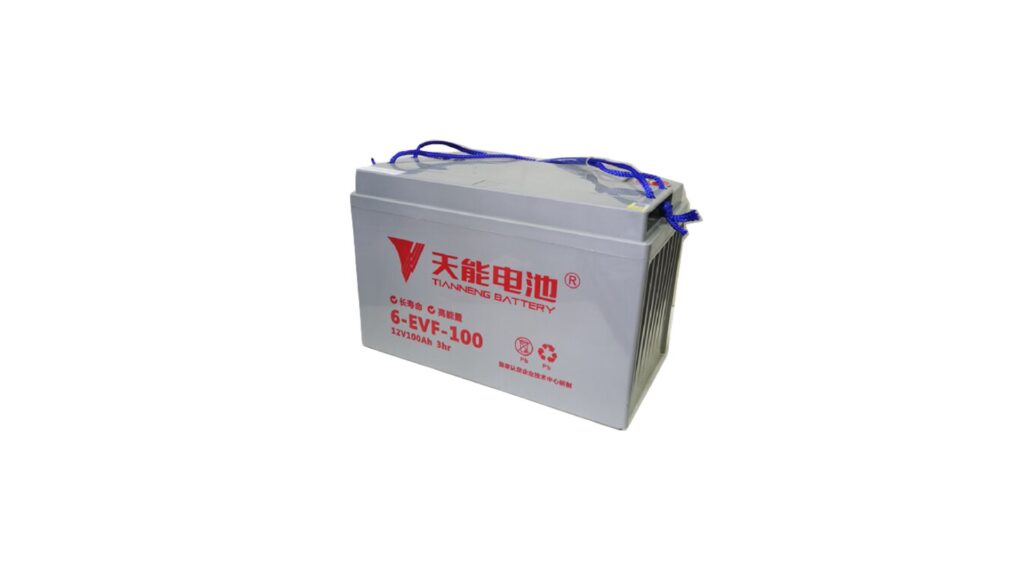

- AGM (Absorbent Glass Mat): Popular for floor scrubbers and sweepers. Maintenance-free, but sensitive to overcharging.

- Flooded Lead-Acid: Reliable but needs regular water topping. Improper care leads to sulfation.

- Lithium-ion: Newer and more expensive, but longer life and fast charging.

Each battery has different charging behaviors, voltage thresholds, and lifespan expectations. For example:

- A healthy 12V AGM battery should show at least 12.7V when fully charged, and no less than 11.8V under load.

- A typical battery pack in a ride-on scrubber might be 24V or 36V — so make sure you’re testing the right configuration.

💡 Tip: Always use the charger recommended by the equipment manufacturer to avoid long-term damage.

🧪 2. How to Perform a Battery Health Test (Step-by-Step)

You don’t need to be an electrician to check your battery. Here’s how we do it in the field — whether it’s a sweeper battery or a scrubber battery.

✅ Step 1: Gather the Tools

- Digital voltmeter or multimeter

- Optional: Battery load tester

- Safety gloves & goggles

✅ Step 2: Do a Visual Check

- Are the terminals corroded or loose?

- Is the case swollen or leaking?

- Is there any burning smell after charging?

Even before you test, visual signs can tell you a lot.

✅ Step 3: Voltage Testing

- Turn off the machine.

- Set your voltmeter to DC volts.

- Touch the red lead to the positive (+), black to negative (–).

- Read the voltage:

- 12.6V–12.8V: Full charge

- 12.4V: 75% charge

- 12.0V: 50% (Needs charging)

- Below 11.8V: Battery may be damaged

If you’re testing a 24V or 36V system, multiply accordingly.

✅ Step 4: Load Testing (Optional but Recommended)

This simulates real usage. You’ll see if your battery can hold up under pressure.

- Attach load tester for 10 seconds.

- Watch if voltage drops below 10.5V under load.

- If it dips too low, your battery’s internal resistance is too high — time to replace or recondition.

✅ Step 5: Charge Test

After charging, does the battery quickly lose power when you start cleaning again? If yes, it might not be holding charge due to plate sulfation or deep cycle fatigue.

⚠️ 3. Why Batteries Fail (And How to Avoid It)

Here’s what I’ve seen most often in our customers’ machines:

🟥 Over-Discharging

Running the machine until it dies repeatedly causes irreversible damage. Your deep cycle battery is strong — but not invincible.

🟥 Long Idle Periods

Leaving your battery idle for weeks or months without charging leads to self-discharge and sulfation. Especially in winter.

🟥 Using the Wrong Charger

I’ve seen people use car chargers on AGM batteries. That’s like feeding diesel to a gasoline engine. It works… until it doesn’t.

🟥 Hot or Cold Storage

Batteries hate extreme temperatures. Hot warehouses? Ice-cold garages? Both will drain and damage cells faster than you think.

🛠️ 4. Daily & Weekly Battery Maintenance Tips

You want to extend battery life? Make these habits part of your routine.

✅ Daily Habits

- Always fully recharge after every shift — don’t partially charge.

- Check cables and connectors for looseness or corrosion.

- Wipe terminals clean of dirt and moisture.

✅ Weekly Habits

- Do a quick voltage test before and after use.

- Log battery performance in a simple spreadsheet.

- Rotate use between machines if possible.

✅ Monthly Habits

- Clean terminals with baking soda and water (for lead-acid batteries).

- Inspect charger output — make sure it’s within spec.

- Train your team! Most battery failures happen because the operator isn’t aware of what kills them.

🔄 5. When to Replace a Battery (And How to Choose Right)

No battery lasts forever.

Here’s when it’s time to say goodbye:

🚩 Warning Signs:

- You charge the battery, but the machine runs only 15–20 minutes.

- You hear clicking noises from the charger, but no full charge completes.

- Battery voltage drops under 10V during operation.

✅ Replacement Tips:

- Match voltage and amp-hour rating exactly.

- Size matters — make sure it fits the compartment.

- We always recommend going OEM (original equipment manufacturer) to ensure compatibility, safety, and warranty.

📘 Ready to Take Control of Your Battery Health?

Maintaining your battery is not complicated. But it is powerful.

With just a few simple habits — and by running a quick battery voltage test once a week — you can double the life of your battery and cut downtime in half.

🎯 Get the Full Guide Now

Want everything I just shared in a printable checklist format?

Click below to get our FREE Battery Health Testing PDF — easy to use, technician-approved, and perfect for your team.

👉 [Contact us to Get the Battery Testing Guide]

🧰 Need Support or Replacement Batteries?

We offer:

- OEM batteries for all major floor scrubber and sweeper brands

- On-site testing & diagnostics by trained technicians

- Annual battery health checks to prevent failure before it happens

💬 Not sure what you need? Reach out anytime. Our team is happy to help.

🛒 Shop Batteries and Parts

Looking for replacement batteries, chargers, or parts for your cleaning machines?

🛒 [Contact us to Get Our Battery Catalog →]

All products are tested, backed by warranty, and ship fast.

🔄 Frequently Asked Questions (FAQ)

Q: How do I know if my sweeper battery is still good?

A: Use a multimeter to test voltage. If fully charged but drops under 11.8V during use, it’s likely near the end of life.

Q: What’s the correct voltage for a healthy AGM battery?

A: 12.6V or higher when fully charged. Under load, it shouldn’t drop below 11.8V.

Q: Can I use a car battery in my floor scrubber?

A: Technically possible, but not recommended. Deep-cycle scrubber batteries are designed for long discharge cycles — car batteries aren’t.

Final Thoughts

You don’t need to be a technician to take control of your battery performance. You just need the right guide, a few tools, and the discipline to check it regularly.

Trust me — your machines will last longer, your team will work more efficiently, and you’ll avoid unexpected repair costs.

If you’ve got any questions, my team and I are just a call or message away. We’re here to help you power through every shift.

Let’s keep your cleaning machines running strong — one battery at a time.