Floor Cleaning Equipment Troubleshooting Guide

Maintenance & Common Problems & Solutions

TINTRODUCTION

Comprehensive Guide:

Maintenance & Troubleshooting

In this guide, we’ll cover:

Common Problems: From poor suction to uneven scrubbing patterns, we’ll identify the typical issues that can arise with floor scrubbers.

Step-by-Step Solutions: You’ll find actionable steps that you can take right away to troubleshoot and fix these problems.

Preventive Tips: Learn how to maintain your machine effectively so that you can avoid these issues in the first place.

TABLE OF CONTENTS

1. Everything You Need to Know about Floor Scrubbers

As someone who has worked extensively in the cleaning equipment industry, I understand the importance of choosing the right floor scrubber for your specific needs. In this guide, I will share everything you need to know about floor scrubbers, including their types, working principles, advantages and disadvantages, pricing, and features across different market segments.

A floor scrubber is an essential cleaning machine designed to efficiently clean various types of flooring surfaces. Unlike traditional cleaning methods that rely on mops and buckets, floor scrubbers automate the process of scrubbing, washing, and drying floors, making them a vital tool in both commercial and industrial settings.

What is a Floor Scrubber?

Floor scrubbers are specialized machines equipped with brushes or pads that scrub the floor while simultaneously dispensing a cleaning solution and vacuuming up the dirty water. This process ensures that floors are not only cleaned but also dried quickly, reducing the risk of slips and falls. They are particularly effective in environments where cleanliness is crucial, such as hospitals, schools, and warehouses.

What is a floor scrubber?

How Do Floor Scrubbers Work?

The operation of a floor scrubber typically involves three main systems:

Automated Dispensing System:

This system dispenses a controlled amount of cleaning solution onto the floor. The solution can vary based on the type of floor being cleaned and the level of dirt present.

Scrubbing System:

The scrubbing mechanism consists of rotating brushes or pads that agitate the cleaning solution on the floor’s surface. This agitation helps to dislodge dirt, grime, and stains effectively.

After scrubbing, a squeegee collects the dirty water and a powerful vacuum system removes it from the floor, storing it in a separate tank for disposal later.

Types of Floor Scrubbers by Working Principle

Floor scrubbers can be categorized based on their working principles into two main types: Rotary Scrubbers and Orbital Scrubbers.

Rotary Scrubbers:

These machines use a circular scrubbing motion to clean floors. They are effective for deep cleaning and are often used in commercial settings. For instance, a rotary scrubber can handle heavy soil and stains on concrete floors effectively.

However, they can be noisy and require more maintenance due to their complex moving parts.

Orbital Scrubbers:

Unlike rotary scrubbers, orbital scrubbers use a back-and-forth motion. This makes them gentler on floors, making them ideal for delicate surfaces like vinyl or polished tiles. They are quieter and easier to maneuver, which is beneficial in environments like schools or offices.

Types of Floor Scrubbers by Usage

Floor scrubbers can also be classified based on their intended usage:

Walk-Behind Scrubbers:

These are typically used for small to medium areas. Users operate them by walking behind the machine. They offer great maneuverability and are suitable for tight spaces.

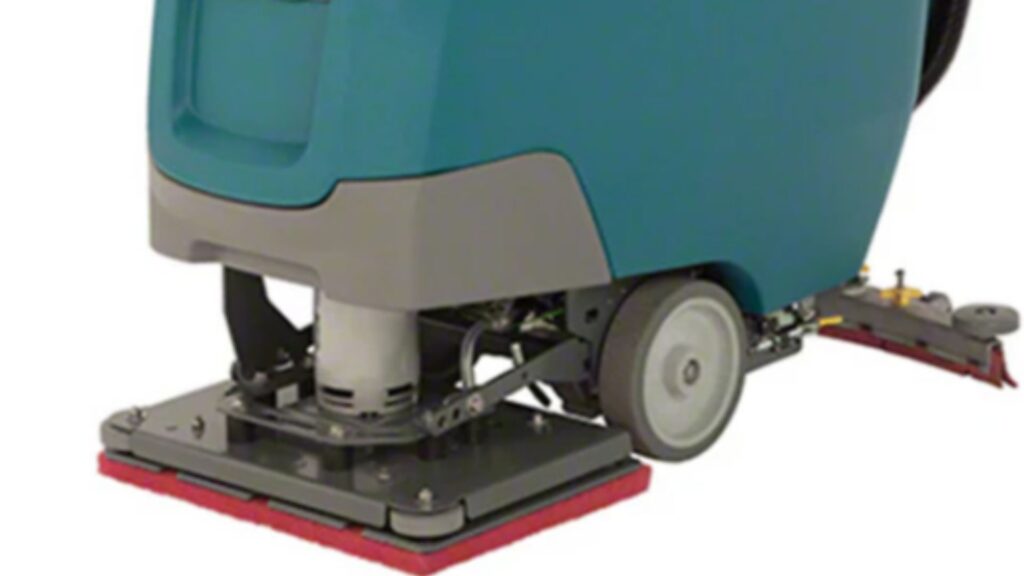

Ride-On Scrubbers:

Designed for larger areas, these machines allow the operator to ride on them, significantly increasing efficiency for extensive cleaning tasks. They usually have larger tanks and wider cleaning paths.

Advantages and Disadvantages of Different Floor Scrubbers

Understanding the pros and cons of various floor scrubbers can help you make an informed decision:

Rotary Scrubbers:

Advantages:

Powerful scrubbing action; effective for deep cleaning; good for high foot traffic areas.

Disadvantages:

Higher maintenance costs; can be noisy; may damage delicate floors if not used correctly.

Orbital Scrubbers:

Advantages:

Gentle on floors; quieter operation; versatile for various applications.

Disadvantages:

May not be as effective on heavy soil compared to rotary models; typically more expensive upfront.

Pricing Ranges of Floor Scrubbers

The cost of floor scrubbers varies widely based on their type and features:

Low-End Models:

Prices range from $1,000 to $3,000. These are usually basic walk-behind models suitable for small businesses or home use.

Mid-Range Models:

Typically priced between $3,000 and $10,000. These models often include additional features like better battery life and larger tanks.

High-End Models:

Prices can exceed $10,000. These machines often come with advanced technology such as automatic chemical dosing and enhanced maneuverability for large commercial spaces.

key factors to consider for different suppliers

When comparing floor scrubbers from different suppliers, there are several key factors to consider:

Practicality and Ease of Use

Kärcher:

Known for user-friendly designs, Kärcher machines are often easy to operate but may not perform as well in heavy-duty cleaning.

Factory Cat:

Offers robust machines practical for various applications. Users find them straightforward to operate.

PowerBoss:

Similar to Factory Cat, PowerBoss scrubbers are designed for ease of use while providing powerful cleaning.

Durability

Kärcher:

Generally considered less durable due to cheaper materials like plastic and aluminum that can crack or bend easily.

Factory Cat & PowerBoss:

Known for rugged construction, these machines often last longer than competitors.

Similar to Factory Cat, PowerBoss scrubbers are designed for ease of use while providing powerful cleaning.

Purchase Costs

Kärcher:

Typically more affordable upfront, appealing to budget-conscious buyers.

Factory Cat & PowerBoss:

Require higher initial investment but offer better performance and durability long-term.

Maintenance Costs

Kärcher:

This can be higher due to frequent part replacements from lower-quality components.

Factory Cat & PowerBoss:

Generally more manageable with readily available parts.

Replacing Parts

Kärcher:

Challenging due to proprietary components, leading to repair delays.

Factory Cat & PowerBoss:

Parts are easier to replace with better access to components.

Cost of Parts & Maintenance

Kärcher:

Parts can be high relative to machine price due to frequent replacements.

Factory Cat & PowerBoss:

Parts are more expensive upfront but less frequent replacements lead to lower overall maintenance costs.

After-Sales Service

Kärcher:

Mixed reviews, with noted issues in service quality and accessibility.

Factory Cat & PowerBoss:

Better customer support, training, and specialized service centers.

In summary

while Kärcher offers affordability, Factory Cat and PowerBoss provide superior durability, performance and long-term value. Considering the total cost of ownership and after-sales support is crucial when selecting the right floor scrubber for your needs.

Evaluating China Leading brand CY floor scrubbers

When evaluating the CY brand floor scrubbers, it’s essential to consider how they compare to other suppliers in terms of practicality, ease of use, durability, purchase costs, maintenance costs, the difficulty of replacing parts, the cost of parts maintenance and replacement, and after-sales service.

Here’s a detailed analysis based on these factors:

Practicality and Ease of Use of CY Brand

CY floor scrubbers are designed to be straightforward and user-friendly. Their focus on innovation means that many models come with intuitive controls, making them easy for operators to learn and use effectively. This practicality is beneficial in environments where multiple users may operate the machine.

Durability of Use of CY Brand

Generally, CY machines are built with quality materials aimed at ensuring a decent lifespan. Based on customer feedback, CY floor scrubbers can last between 5 to 10 years with proper maintenance. However, their durability may not match that of higher-end brands like Factory Cat or PowerBoss, which are known for their rugged construction.

Purchase Costs of CY Brand

The purchase cost of CY floor scrubbers is typically competitive, making them an attractive option for budget-conscious buyers. Prices generally range roughly several thousand dollars depending on the model and features. This affordability can be appealing for small to medium-sized businesses looking for effective cleaning solutions without a significant upfront investment.

Maintenance Costs of CY Brand

Maintenance costs for CY scrubbers are generally reasonable. Regular maintenance is essential to prolong the lifespan of the equipment, but users have reported that parts are relatively affordable compared to some competitors. However, as with any brand, the frequency of use and care taken will impact overall maintenance expenses.

Replacing Parts of CY Brand

Replacing parts on CY floor scrubbers is typically manageable. The design allows for easier access to components that require regular maintenance or replacement. However, since some parts may be proprietary, you may think of sourcing replacements could take longer than with more widely used brands. Actully not, because CY after-sale service team service well with original quality parts in time.

Cost of Parts Maintenance and Replacement of CY Brand

The cost associated with maintaining and replacing parts for CY scrubbers tends to be lower than average. Users appreciate that common wear items such as brushes and pads are affordable and readily available through authorized distributors.

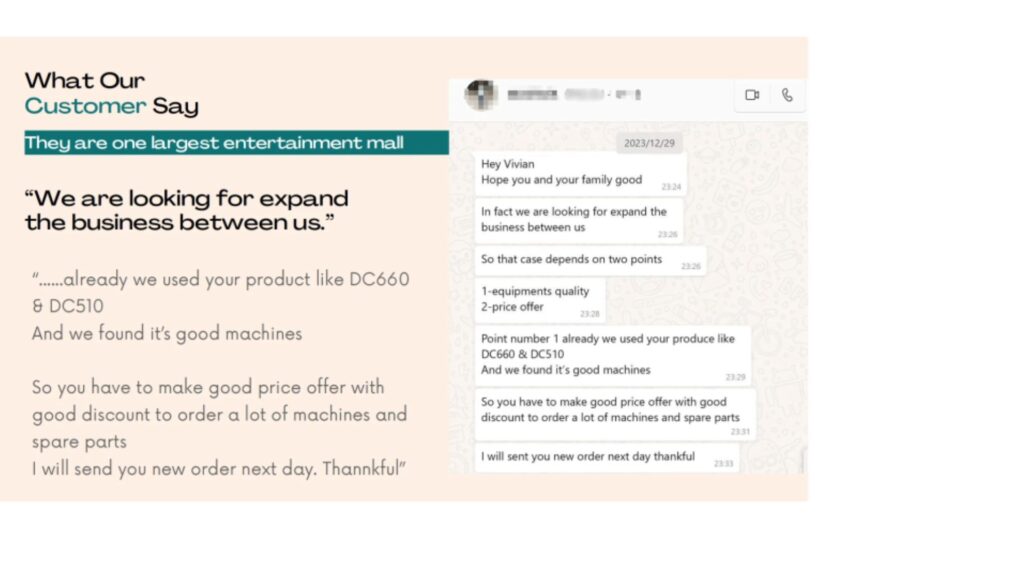

Case Study: D** C** Mall's Success with CY Cleaning Machines

D** C** Mall, located in the bustling heart of Iraq, is not just a shopping destination; it’s a vibrant community hub that brings together retail, dining, and entertainment. With its expansive layout and diverse offerings, the mall attracts thousands of visitors daily, making cleanliness a top priority for its management.

To ensure a pristine environment for shoppers and tenants alike, D** C** Mall has relied on CY’s advanced cleaning solutions for over five years. This partnership has proven to be beneficial, showcasing the effectiveness of our machines in a demanding commercial setting.

Customer Overview

The mall operates a fleet of 16 CY cleaning machines:

• DC660 Rider Scrubbers: 12 sets

• DC510 Walk-Behind Scrubbers: 4 sets

• CYS140 Rider Sweeper: 1 set

These machines have become integral to the mall’s cleaning operations, ensuring that every corner is spotless and welcoming. The combination of rider and walk-behind scrubbers allows for flexibility in cleaning various areas, from wide-open spaces to tight corners.

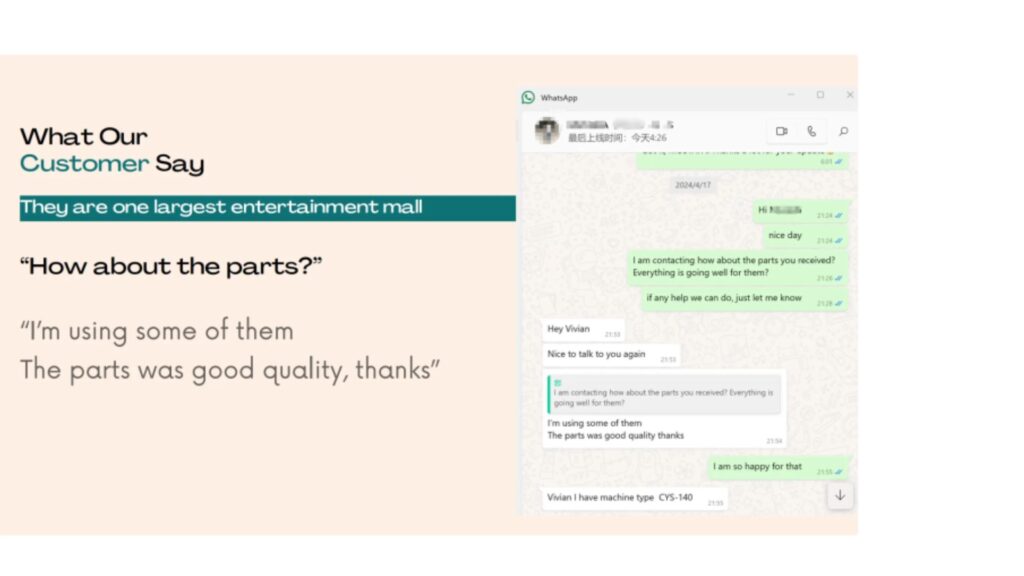

The Customer Interaction Story

Our journey with the customer began when he reached out via WhatsApp to inquire about spare parts for his existing machines.

He found my contact information through our official website after realizing he needed assistance with maintenance. Interestingly, he acquired these machines over four years ago through trading friends who frequently traveled to China, rather than directly from our factory. Despite not having direct contact with us previously, the customer felt compelled to reach out due to our strict distributor protection policies.

After confirming that he had no existing relationships with distributors, he was relieved to find my contact information online. This marks the beginning of a fruitful relationship built on trust and mutual benefit.

Machine Performance and Maintenance

The machines purchased in June 2019 have been remarkably reliable. Over nearly five years of use, the customer reported no major failures, attributing this success to their robust design and ease of maintenance.

The mall’s staff has managed daily upkeep without needing professional guidance, demonstrating the user-friendly nature of CY machines.

The customer provided a detailed list of required spare parts, which included common wear items such as:

Notably, they had sufficient stock of brushes and squeegees from their initial order four years ago, indicating effective inventory management. This foresight has allowed them to maintain operational efficiency without interruption.

Cost Analysis

The total cost for the requested spare parts amounted to $7,594.

The customer expressed satisfaction with this pricing, highlighting the affordability of maintaining CY machines compared to competitors.

In an industry where operational costs can quickly escalate, our commitment to providing high-quality yet affordable solutions has resonated well with our clients.

Customer Feedback After Five Years

After five years of using the DC660 and DC510 models, the customer shared positive feedback:

They have found your machines to be reliable and efficient. He emphasized the importance of competitive pricing for future orders, indicating his intention to continue investing in CY products.

This endorsement reflects not only satisfaction with our products but also confidence in our ongoing support.

Reliability and Longevity of CY Machines

This case underscores several key benefits of CY cleaning machines:

• Ease of Use and Maintenance: Designed for straightforward operation, even for staff without extensive training.

• Durability: High-quality construction allows for over five years of effective service; with proper maintenance, these machines can last even longer.

• Affordability: Competitive pricing ensures a low total cost of ownership, making it easier for businesses like D** C** Mall to manage budgets effectively.

After-Sales Service of CY Brand

CY offers a decent level of after-sales service, with support available through their network of distributors across China. They emphasize quality control and customer satisfaction but may not have the same extensive service network or reputation as larger brands like Kärcher or PowerBoss. Customers should inquire about local service options when considering a purchase.

Conclusion

Addressing Customer Concerns About After-Sales Service

When customers inquire about purchasing directly from us in China, they often have questions regarding after-sales service and part guarantees. Here’s how we address these concerns:

• After-Sales Service: We provide comprehensive support through a dedicated service team ready to assist with any issues that may arise post-purchase. Our team is trained to handle inquiries promptly and efficiently.

• Parts Guarantee: All spare parts are guaranteed for quality and compatibility with your machines. We ensure that customers receive genuine parts that meet our high standards. This commitment helps prevent downtime caused by incompatible or substandard components.

• Downtime Management: We understand that machine downtime can significantly impact operations. Our swift response times and efficient logistics minimize downtime during repairs. We strive to ensure that any necessary repairs are completed quickly so that your operations can continue smoothly.

Real-Life Troubleshooting Experience

An interesting aspect of this case study is the troubleshooting experience with the CYS140 Rider Sweeper purchased in 2020. The machine faced an issue with its control board after being exposed to rain over time.

The customer was able to resolve this issue independently by replacing the control board—a cost-effective solution amounting to just $64 (including shipping).

Notably, after placing the order through FedEx for the replacement parts from China, the customer received them within just seven days—a testament to our efficient logistics and commitment to minimizing downtime. This incident highlights not only the reliability of our products but also their ease of repair and maintenance.

Conclusion

In summary, CY floor scrubbers present a balanced option for users seeking practical and cost-effective cleaning solutions. While they may not offer the same level of durability or advanced features as some premium brands, they provide good value for money with user-friendly designs and reasonable maintenance costs. When selecting a floor scrubber, it’s crucial to weigh these factors against your specific cleaning needs and budget constraints to ensure you make an informed decision.

Personal Experience with Floor Scrubbers

In my experience using various floor scrubbers, I have found that investing in a high-end model pays off in the long run due to its durability and efficiency. For instance, when managing a large warehouse, switching from a walk-behind model to a ride-on scrubber significantly reduced cleaning time and labor costs.

In summary

Choosing the right floor scrubber is crucial for maintaining clean environments efficiently. By understanding the different types available based on working principles and usage, along with their advantages and disadvantages, you can make an informed decision that meets your specific needs. Whether you’re looking for cost-effective solutions or advanced technology in cleaning equipment, there is a floor scrubber that will suit your requirements perfectly.

I hope this comprehensive guide helps you navigate the world of floor scrubbers effectively! If you have any questions or need further assistance in selecting the right machine for your needs, feel free to reach out!

2. Choose Right Floor Scrubber Guide

Selecting the right floor scrubber is crucial for maintaining cleanliness and efficiency in any facility. As someone deeply involved in the cleaning equipment industry, I want to share my insights on how to choose the best floor scrubber for your needs.

This guide will cover the different types of floor scrubbers, their working principles, budget considerations, and how to evaluate brands for the best value. Additionally, we’ll explore how to align your specific cleaning needs with the right equipment.

Understanding Different Types of Floor Scrubbers

Floor scrubbers come in various types, each designed for specific cleaning tasks. Here’s a breakdown of the most common types:

1. Walk-Behind Scrubbers

Working Principle:

These machines are operated by a person walking behind them. They dispense a cleaning solution onto the floor, scrub with rotating brushes or pads, and then vacuum up the dirty water.

Example: Ideal for small to medium-sized areas like retail stores or office spaces, walk-behind scrubbers are highly maneuverable and can handle various floor types effectively.

2. Ride-On Scrubbers

Working Principle:

Working Principle: Designed for larger areas, these machines allow the operator to sit while cleaning. They feature larger tanks and wider cleaning paths, enhancing productivity.

Example: In large warehouses or manufacturing facilities, ride-on scrubbers can significantly reduce cleaning time and operator fatigue while covering expansive floor areas efficiently.

3. Rotary Floor Scrubbers

Working Principle:

Rotary scrubbers use a circular scrubbing motion to clean floors. The rotating brushes or pads agitate the surface and lift dirt effectively.

Example: These machines are versatile and can be used on various surfaces, including tile and concrete. They are particularly effective for heavy-duty cleaning tasks where deep scrubbing is required.

4. Orbital Floor Scrubbers

Working Principle:

Orbital scrubbers utilize a unique oscillating motion that allows for more effective scrubbing without damaging the floor surface. The pads move in a circular motion but also shift side-to-side.

Example: These scrubbers are excellent for delicate surfaces like polished concrete or hardwood floors, providing a thorough cleaning without causing wear.

5. Automatic Floor Scrubbers

Working Principle:

Automatic scrubbers are designed to clean floors with minimal human intervention. They use sensors and pre-programmed routes to navigate and clean the floor efficiently.

Example: These machines are ideal for large, open spaces like warehouses, shopping malls, or airports. They can operate for extended periods without the need for constant supervision, ensuring consistent cleanliness.

Assessing Your Specific Cleaning Needs

Before making a purchase, it’s essential to consider your unique cleaning requirements:

Size of the Area:

Evaluate the size of the space you need to clean. For smaller areas, a walk-behind scrubber may suffice; however, larger facilities may benefit from ride-on or automatic models that can cover more ground quickly.

Type of Flooring:

Different floors require different cleaning approaches. For instance:

Hardwood Floors:

Opt for orbital scrubbers that provide gentle yet effective cleaning.

Concrete Floors:

Rotary or walk-behind scrubbers can handle heavy-duty tasks.

Tile Floors: Both rotary and walk-behind models can work well here but ensure they have appropriate pads to avoid scratching.

Frequency of Use:

Consider how often you will be using the floor scrubber:

If you need daily cleaning in high-traffic areas, investing in a durable ride-on or automatic scrubber may be worthwhile.

For less frequent use or smaller tasks, a walk-behind model might be sufficient.

Cleaning Solution Preferences:

Some facilities prefer eco-friendly cleaning solutions or specific chemicals that require compatibility with certain machines. Ensure that your chosen scrubber can accommodate your preferred cleaning agents.

Noise Levels:

If you operate in noise-sensitive environments (like schools or hospitals), look for low-noise models that won’t disrupt daily activities.

Storage Space:

Consider where you will store your equipment when not in use. Some models are more compact than others and may fit better in limited storage areas.

Budget Considerations

When choosing a floor scrubber, it’s essential to factor in your budget. While it may be tempting to select the cheapest option available, consider the long-term value of your investment. Higher-quality machines may have a higher initial cost but often lead to lower maintenance expenses and better performance over time. Think about how much you’re willing to spend upfront versus what you’ll save in maintenance and operational costs.

Evaluating Brands for Good Value

Different brands offer unique advantages and disadvantages that can impact your decision. To find a truly good value floor scrubber, consider these characteristics:

Reasonable Purchase Price:

Ensure that the initial cost aligns with your budget without compromising quality.

Reliable Quality:

Brands like CY use imported controllers that enhance stability and performance, promising over five years of reliable use.

Low Noise Levels:

Machines designed for quieter operation are beneficial in environments like schools or hospitals where noise can be disruptive.

Ease of Use and Maintenance:

User-friendly controls and straightforward maintenance procedures save time and effort.

Low Fault Rates:

Machines with a history of low breakdown rates minimize downtime and repair costs.

Affordable Maintenance Costs:

Check the availability and pricing of replacement parts before making a purchase.

Long Battery Life:

For battery-operated models, extended runtime is crucial for uninterrupted cleaning sessions.

Professional After-Sales Service:

Reliable customer support can make a significant difference in resolving issues quickly.

Positive Industry Reputation:

Look for brands with good reviews in the cleaning industry; this often reflects their reliability and performance.

For instance, CY floor scrubbers not only meet these criteria but also have garnered positive feedback from users across various sectors.

Personal Insights

Reflecting on my own experiences with floor scrubbers, I’ve learned that investing in quality equipment pays off significantly over time. Initially, I chose a budget model that seemed appealing due to its low price but soon realized it required frequent repairs and had limited capabilities. Transitioning to a reputable brand made all the difference; not only did it perform better, but it also saved me money on maintenance over time.

Conclusion

Choosing the right floor scrubber involves understanding your specific needs—such as area size, flooring type, frequency of use—and evaluating different brands based on their strengths and weaknesses within your budget constraints. By following this guide, you can make an informed choice that enhances your cleaning operations while providing excellent value for your investment.

Remember, the right machine will not only improve cleanliness but also contribute to a safer environment for everyone who uses your facility. Take your time to research and choose wisely; your efforts will pay off!

3. Scrubbers Troubleshooting Guide & Solutions

As a company that manufactures cleaning equipment like floor scrubbers and sweepers, we understand the importance of keeping your machines running smoothly. In this comprehensive guide, we’ll cover common floor scrubber problems and provide detailed solutions to help you maintain your equipment and achieve optimal cleaning results.

Problem No 1: The Scrubber Doesn't Power On

If your floor scrubber won’t turn on, the first thing to check is whether it’s properly plugged in or the battery is charged.

For corded models, ensure the power cord is securely connected to both the machine and the outlet. Test the outlet by plugging in another device to confirm it’s working. If the outlet is faulty, reset the circuit breaker.

For battery-powered scrubbers, check the battery charge level. If the battery is low or dead, charge it fully before use. If the battery is adequately charged but the machine still won’t power on, there may be an issue with the electrical components or wiring. In this case, contact an authorized service technician for further assistance.

Additional Tips:

Inspect the power switch for any damage. A faulty switch can prevent the machine from powering on.

Ensure that all safety features are engaged; some models have safety locks that must be activated before operation.

Check the circuit breaker on the machine itself. If it has tripped, reset it and try powering on the scrubber again.

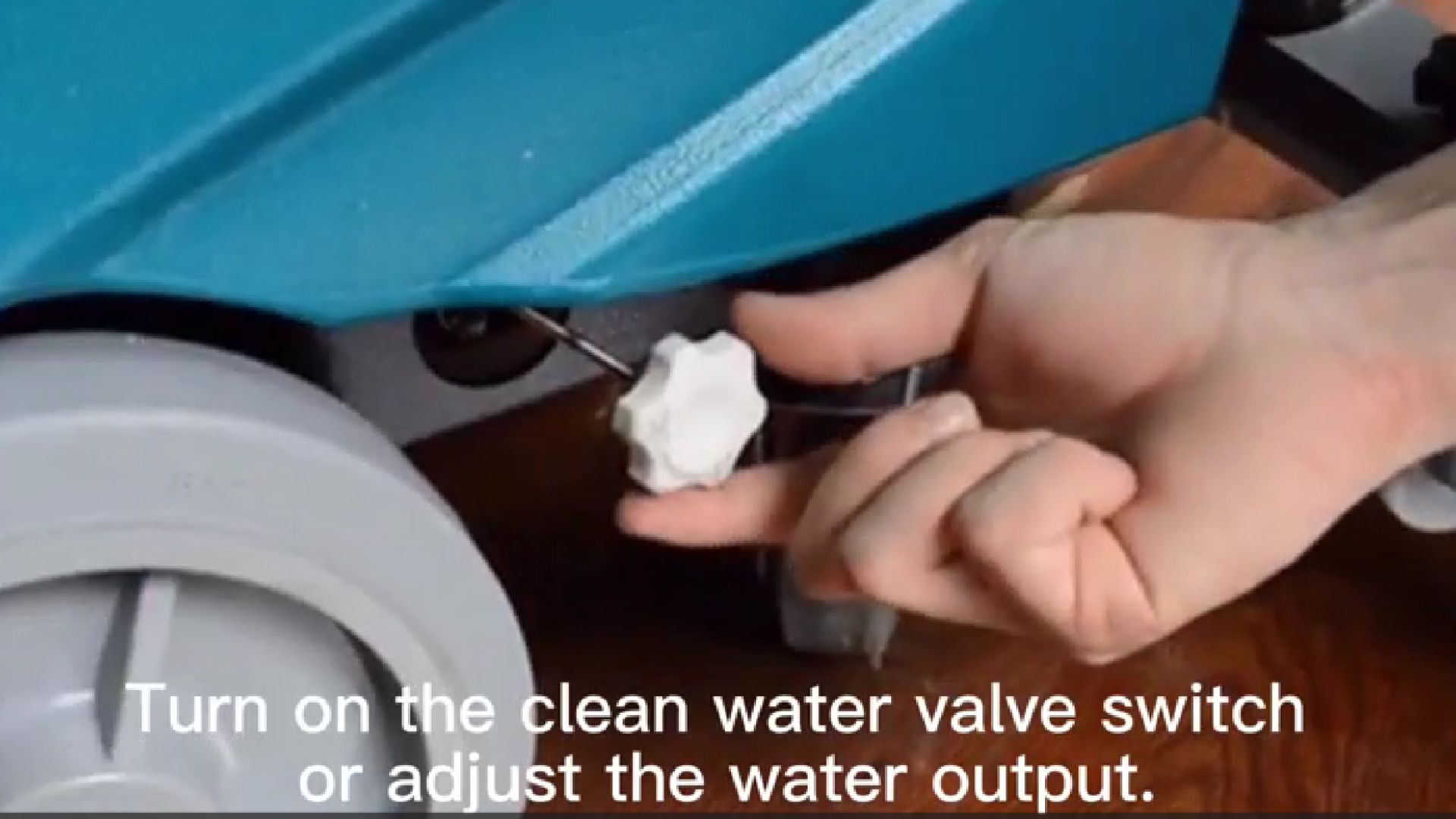

Problem No 2: The Scrubber Doesn't Release Water

If your floor scrubber is not releasing water, it could be due to several reasons:

Empty solution tank:

Ensure the solution tank is filled to the proper level with water and cleaning solution.

Clogged hoses or valves:

Check the solution tank hoses and valves for any blockages. Remove debris and flush the system with clean water.

Clogged solution tank filter:

A dirty or clogged filter can prevent water flow. Remove and clean the filter thoroughly. If the filter is damaged, replace it.

Faulty solution pump:

If the solution pump is malfunctioning, it may not be able to deliver water to the brush. This issue requires professional repair.

Example Scenario:

I once had a customer who faced this issue during a busy cleaning session. After checking the tank and finding it empty, they quickly refilled it and were back in business within minutes! Another time, a clogged hose was the culprit, and a thorough flushing did the trick.

Problem No 3: Poor Dirty Water Pick Up

If your floor scrubber is leaving behind excessive amounts of dirty water, there are a few things to check:

Full recovery tank:

Empty the recovery tank if it’s full. A full tank can prevent the machine from picking up water effectively.

Damaged or misaligned squeegee:

Inspect the squeegee for wear and tear. Replace the squeegee blade if it’s cracked or damaged. Ensure the squeegee is properly aligned and making full contact with the floor.

Clogged vacuum hose:

Use a broom handle to clear any debris from the vacuum hose. You can also flush the hose with water to remove blockages.

Faulty vacuum motor:

If the vacuum motor is not working correctly, it can lead to poor suction. This issue requires professional diagnosis and repair.

Personal Insight:

I remember working on a particularly stubborn stain at a client’s facility; after ensuring everything was clear and aligned, we achieved perfect suction and left their floors spotless! Another time, a clogged vacuum hose was the culprit, and a quick fix with a broom handle solved the problem.

Problem No 4: Poor Scrubbing Results

If your floor scrubber is leaving behind dirt and debris, consider these factors:

Incorrect brush or pad selection:

Choose the appropriate brush or pad for the floor type and cleaning requirements. Harder floors like concrete may require coarser brushes or pads.

Improper pad pressure:

Ensure that pad pressure is set correctly; excessive pressure can lead to poor cleaning results and increased energy consumption.

Incorrect chemical usage:

Use recommended cleaning chemicals for your specific floor type and scrubber model. Avoid mixing chemicals as they may not be compatible and could reduce cleaning effectiveness.

Worn or damaged brushes:

Inspect brushes for wear and replace them if necessary; dirty or clogged brushes can also impact cleaning performance.

Example:

One time, I had a team using an incorrect pad on a vinyl floor; after switching to a softer pad designed for that surface, their results improved dramatically! Another issue we encountered was using too much chemical, which left a sticky residue on the floor. Adjusting the chemical concentration solved the problem.

Problem No 5: The Machine is Not Sucking All the Dirty Water Up

If your floor scrubber is leaving streaks of water behind, it could be due to:

Worn or misaligned squeegee:

Inspect the squeegee for wear and ensure it’s properly aligned; replace if necessary.

Full recovery tank:

Empty it if full; a full tank can prevent effective water pickup.

Poor seal on recovery tank Lid:

Check the seal’s airtightness. Replace it if neccessary.

Clogged vacuum hose:

Clear any debris from it using a broom handle; flushing with water can also help remove blockages.

Faulty vacuum motor:

If not working correctly, this requires professional diagnosis and repair.

Additional Tip:

Check the squeegee blades for any nicks or cuts that may be causing uneven suction. Replacing the blades can often resolve this issue.

Conclusion

By following these troubleshooting steps and performing regular maintenance, you can keep your floor scrubber running at peak efficiency and ensure your floors are cleaned to perfection every time. Remember, if you encounter any issues that you’re unsure how to resolve, it’s best to contact an authorized service technician for professional assistance.

Investing time in understanding these common problems not only prolongs your equipment’s lifespan but also enhances your overall cleaning efficiency—making every cleaning session more effective! With proper care and attention, your floor scrubber will continue to deliver reliable performance for years to come.

4. Floor Scrubber Maintaince Guide and Solutions

Optimize Performance and Extend Machine Life

As a company dedicated to providing high-quality cleaning equipment, we understand the importance of proper maintenance in ensuring the longevity and efficiency of your floor scrubbers. In this comprehensive guide, we will share valuable insights and practical solutions to help you get the most out of your investment.

Preparation:

Setting the Stage for Effective Cleaning

Before you begin scrubbing, it’s crucial to prepare your machine for optimal performance. Here are some key steps to follow:

Inspect the machine:

Thoroughly check for any signs of damage or wear and tear. Pay special attention to the brushes, pads, and squeegees, ensuring they are in good condition and properly installed.

Clean the tanks:

Empty and rinse the solution and recovery tanks to remove any debris or residue from previous uses. This will prevent the buildup of dirt and ensure that your machine is ready to tackle the job at hand.

Check the battery:

Ensure that your machine is fully charged and ready to go. If you’re using a battery-powered scrubber, make sure to follow the manufacturer’s instructions for charging and maintenance.

Prepare the area:

Before scrubbing, sweep or dry mop the floor to remove any loose debris. This will help prevent the machine from pushing dirt around and ensure a more thorough cleaning.

By following these simple steps, you’ll set your floor scrubber up for success and enjoy better cleaning results.

Post-Use Maintenance:

Keeping Your Machine in Top Shape

After each use, it’s essential to properly maintain your floor scrubber to extend its lifespan and prevent costly repairs.

Here’s what you should do:

Empty and clean the tanks:

Drain the solution and recovery tanks and rinse them thoroughly with clean water. This will prevent the buildup of dirt and odors, which can lead to machine malfunctions.

Clean the brushes or pads:

Remove the brushes or pads and rinse them under running water. This will remove any debris or cleaning solution that may have accumulated during use. Allow them to air dry before storing or replacing them.

Clean the squeegees:

Wipe down the squeegees with a clean cloth to remove any dirt or debris. Check for wear and tear and replace them if necessary.

Wipe down the machine:

Use a damp cloth to wipe down the exterior of the machine, paying special attention to any areas that may have come into contact with cleaning solution or dirt.

Store the machine properly:

Store your floor scrubber in a clean, dry place, with the brushes or pads removed and the tanks empty. This will prevent any damage or corrosion and ensure that your machine is ready for its next use.

By following these maintenance tips, you’ll keep your floor scrubber in top condition and enjoy a longer lifespan for your investment.

Troubleshooting Common Issues

Even with proper maintenance, you may encounter occasional issues with your floor scrubber. Here are some common problems and solutions:

Poor cleaning performance:

If your machine is not cleaning effectively, check the brushes or pads for wear and tear. Replace them if necessary and ensure that you are using the correct cleaning solution for your floor type.

Excessive foaming:

If you notice excessive foaming in the recovery tank, it may be due to the use of an incompatible cleaning solution. Switch to a low-foaming solution and ensure that you are using the correct dilution ratio.

Water leaks:

If you notice water leaks from the machine, check the hoses and fittings for any cracks or damage. Replace any worn parts and ensure that all connections are tight.

Battery issues:

If your battery-powered scrubber is not holding a charge or running for shorter periods, it may be time to replace the battery. Follow the manufacturer’s instructions for battery maintenance and replacement.

By addressing these issues promptly and following the manufacturer’s recommendations, you’ll keep your floor scrubber running smoothly and enjoy a longer lifespan for your investment.

Conclusion

Proper maintenance is the key to getting the most out of your floor scrubber investment. By following the tips outlined in this guide, you’ll optimize the performance of your machine, reduce downtime, and enjoy a longer lifespan for your investment.

Remember, regular maintenance is an investment in the long-term success of your cleaning operations. By taking the time to properly care for your floor scrubber, you’ll enjoy better cleaning results, lower operating costs, and a cleaner, healthier environment for your staff and customers.

If you have any questions or need further assistance, don’t hesitate to reach out to our team of experts. We’re here to help you get the most out of your cleaning equipment and achieve your cleaning goals.

5. Everything You Need to Know about Floor Scrubber and Sweeper's Battery

When it comes to maintaining a clean and efficient workspace, floor scrubbers play an essential role. However, the heart of these machines—the battery—often goes overlooked. Understanding the intricacies of floor scrubber batteries can significantly enhance your cleaning operations, making your investment worthwhile. Let’s dive into everything you need to know about these vital components.

Why Battery Choice Matters

Choosing the right battery for your floor scrubber is crucial for several reasons:

Performance: The battery directly impacts how long your scrubber can run before needing a recharge. A high-capacity battery allows for extended cleaning sessions without interruptions.

For example, if your facility requires multiple cleaning cycles throughout the day, a robust battery can ensure that you don’t have to stop frequently to recharge.

Cost Efficiency:

Investing in a quality battery can reduce long-term costs. Cheaper batteries may save you money upfront but often lead to more frequent replacements and maintenance issues. Over time, the savings from fewer replacements and less downtime can far outweigh the initial investment in a better battery.

Environmental Impact:

The type of battery you choose can also affect your company’s sustainability efforts. Opting for environmentally friendly batteries can enhance your brand’s reputation and appeal to eco-conscious customers. For instance, lithium-ion batteries are often recyclable and have a lower environmental footprint compared to traditional lead-acid batteries.

Types of Batteries Used in Floor Scrubbers

There are primarily three types of batteries used in floor scrubbers:

Lead-Acid Batteries:

These are the most common and cost-effective option. They are reliable but require regular maintenance and have a shorter lifespan compared to other types. Lead-acid batteries typically last around 1-2 years with proper care but may require water refills and regular equalization charging to maintain performance.

Types of Lead-Acid Batteries

Lead-acid batteries are widely used in floor scrubbers due to their reliability and cost-effectiveness. There are two main types of lead-acid batteries: flooded (or wet) lead-acid batteries that require regular maintenance and sealed lead-acid batteries that are maintenance-free.

Flooded Lead-Acid Batteries

Flooded lead-acid batteries are generally less expensive than other battery types, making them a popular choice for budget-conscious operations.

They can deliver high surge currents, which is beneficial for applications requiring quick bursts of power.

Lead-acid batteries have a well-established recycling process, allowing for the recovery of lead and sulfuric acid.

Disadvantages of Flooded Lead-Acid Batteries

These batteries require regular watering to maintain electrolyte levels, which can be cumbersome. Users must check the fluid levels frequently and top them off with distilled water.

Flooded batteries typically have a shorter cycle life compared to sealed options, especially if they are frequently deep-cycled.

They tend to be heavier and bulkier than other battery types, which may affect the overall maneuverability of the scrubber.

Price Range:

Flooded lead-acid batteries typically range from $100 to $300 depending on capacity and brand.

Example:

A facility manager at a local warehouse shared that they opted for flooded lead-acid batteries for their scrubbers due to their lower initial cost. However, they quickly realized that the maintenance required was time-consuming. They found themselves regularly checking water levels and adding distilled water, which detracted from their cleaning operations.

2. Sealed Lead-Acid Batteries (Maintenance-Free)

Advantages:

No Maintenance Required:

Sealed lead-acid batteries do not require watering or regular maintenance, making them easier to manage.

Safety:

These batteries are less likely to leak acid or emit harmful gases during operation.

Longer Cycle Life:

They generally offer a longer cycle life compared to flooded versions, especially in applications with frequent discharging.

Disadvantages:

Higher Initial Cost:

Sealed lead-acid batteries tend to be more expensive upfront than flooded options.

Limited Discharge Depth:

They may not handle deep discharges as well as flooded batteries, potentially reducing their lifespan if regularly over-discharged.

Price Range:

Sealed lead-acid batteries usually cost between $150 and $400 based on specifications.

Example:

A cleaning service owner mentioned that they switched to sealed lead-acid batteries for their floor scrubbers after experiencing issues with flooded versions. The convenience of not having to maintain water levels was a game-changer for them, allowing their team to focus more on cleaning rather than battery upkeep.

3. Lithium-Ion Batteries:

Known for their lightweight and longer lifespan, lithium-ion batteries are becoming increasingly popular. They offer faster charging times—often fully charged in just a couple of hours—and do not require maintenance, making them an excellent choice for busy operations.

Additionally, they can last up to 5 years or more, making them a smart long-term investment.

Advantages

1. High Energy Density

Li-ion batteries boast an impressive energy density, allowing them to store a large amount of energy in a compact and lightweight form. This characteristic makes them ideal for portable electronic devices where space and weight are critical considerations.

2. Long Cycle Life

Li-ion batteries typically have a longer cycle life compared to other rechargeable batteries. They can undergo hundreds to thousands of charge-discharge cycles without significant loss of capacity, contributing to their durability and longevity.

3. Quick Charging

Li-ion batteries support fast charging, allowing users to replenish their devices’ power quickly. This is especially crucial in today’s fast-paced world where individuals rely heavily on electronic gadgets and need a rapid turnaround for their battery charging needs.

4. Low Self-Discharge Rate

Li-ion batteries exhibit a low self-discharge rate, meaning they lose less energy when not in use. This makes them suitable for applications where the device may be idle for extended periods without the need for frequent recharging.

5. Versatility

Li-ion batteries come in various forms, including cylindrical, prismatic, and pouch cells, offering flexibility to cater to different applications. This versatility has contributed to their adoption in diverse industries, from consumer electronics to electric vehicles and energy storage systems.

Disadvantages of Lithium-Ion Batteries

1. High Cost

One of the primary drawbacks of Li-ion batteries is their relatively high production cost. This aspect can make devices and technologies utilizing Li-ion batteries more expensive, impacting accessibility for some consumers.

2. Safety Concerns

While Li-ion batteries are generally safe, they can be prone to overheating and, in rare cases, may catch fire or explode. The incidents are often linked to manufacturing defects, improper use, or external factors such as physical damage.

3. Limited Resource Availability

Lithium is not an abundant resource, and the demand for Li-ion batteries has raised concerns about the availability of this crucial element. This has led to exploration of alternative technologies and recycling initiatives to mitigate resource scarcity.

4. Environmental Impact

The production and disposal of Li-ion batteries can have environmental implications. Extraction of lithium and other materials for battery production may lead to habitat disruption, and improper disposal can contribute to pollution.

5. Temperature Sensitivity

Li-ion batteries are sensitive to temperature extremes. High temperatures can accelerate their aging process and reduce performance, while low temperatures can hinder their ability to deliver power effectively.

Pricing Range of Lithium-Ion Batteries

The pricing of Li-ion batteries can vary depending on factors such as capacity, form factor, and brand. Generally, Li-ion batteries range from around $100 to $400 for consumer electronics applications. However, for larger applications like electric vehicles and energy storage systems, the cost can be significantly higher due to the scale and complexity involved.

For example

A high-quality 18650 Li-ion battery cell (commonly used in laptops and power tools) may cost between $5 to $10, while a battery pack for an electric vehicle can range from $5,000 to $15,000 or more, depending on the vehicle model and battery capacity.

Conclusion

Lithium-ion batteries have become the preferred choice for many applications due to their impressive advantages. However, their high cost, safety concerns, and environmental impact must be carefully considered. As technology continues to advance, addressing these drawbacks will be crucial to ensuring the sustainable and widespread use of Li-ion batteries in the future.

When selecting Li-ion batteries for your applications, it’s essential to weigh the advantages and disadvantages based on your specific needs and budget. By understanding the pricing range and making informed decisions, you can maximize the benefits of this powerful technology while minimizing potential risks.

4. Gel Batteries:

These are a subtype of lead-acid batteries that are sealed and maintenance-free. They perform well in various temperatures but can be more expensive than traditional lead-acid options. Gel batteries are particularly useful in environments where spills could be hazardous or where maintenance access is limited.

Advantages of Gel Batteries

Maintenance-Free:

One of the most significant advantages of gel batteries is that they are virtually maintenance-free. Unlike flooded lead-acid batteries that require regular topping up with distilled water, gel batteries do not need this maintenance, making them easier to manage.

Safety:

Gel batteries are sealed and less prone to leakage. This feature reduces the risk of acid spills, which can be hazardous in commercial cleaning environments. Additionally, they emit minimal fumes during operation, allowing for safer indoor use without the need for extensive ventilation.

Good Low-Temperature Performance:

Gel batteries perform well in low-temperature conditions, maintaining their efficiency even when the temperature drops. This characteristic is particularly beneficial for cleaning operations in colder climates or during winter months.

Vibration Resistance:

The gel electrolyte helps absorb vibrations and shocks, making these batteries ideal for use in environments where equipment may be subjected to rough handling or movement.

Long Lifespan:

Gel batteries typically have a longer service life compared to traditional lead-acid batteries, often lasting between 3 to 7 years with proper care and usage.

Disadvantages of Gel Batteries

Higher Initial Cost:

Gel batteries usually come with a higher price tag than flooded lead-acid options. The initial investment can range from $150 to $400 depending on capacity and brand, which may deter some buyers.

Longer Charging Time:

Gel batteries require longer charging times compared to other types of batteries. Charging can take anywhere from 6 to 10 hours to reach full capacity, which may not be ideal for operations needing quick turnaround times.

Limited Discharge Depth:

While gel batteries can handle deep discharges better than some other types, they still have limitations. Regularly discharging them below 50% can significantly reduce their lifespan.

Special Charging Requirements:

Gel batteries require specific chargers designed for their chemistry. Using the wrong charger can lead to overcharging or undercharging, both of which can damage the battery.

Pricing Range of Gel Batteries

Small Capacity (e.g., 12V 35Ah): These typically range from $150 to $200 and are suitable for smaller equipment or applications.

Medium Capacity (e.g., 12V 100Ah): Prices generally fall between $250 and $350, making them suitable for larger cleaning machines like floor scrubbers.

High Capacity (e.g., 12V 200Ah): These can cost anywhere from $400 to $600 and are often used in more demanding applications such as industrial cleaning machines or backup power systems.

Example:

A property manager shared their experience with switching from flooded lead-acid batteries to gel batteries in their floor scrubbers. They initially hesitated due to the higher cost of gel batteries but found that the maintenance-free aspect saved them time and labor costs in the long run. They invested in a high-capacity gel battery priced at around $350 and reported improved performance and reliability during their cleaning operations.

Conclusion

Gel batteries offer a compelling option for powering floor scrubbers due to their maintenance-free nature, safety features, and long lifespan. While they come with a higher initial cost and specific charging requirements, the long-term benefits often outweigh these drawbacks.

Understanding the advantages and disadvantages of gel batteries will help you make informed decisions about your cleaning equipment’s power source. If you’re considering upgrading your floor scrubber’s battery system or looking for more information on suitable options for your operations, feel free to reach out! We’re here to help you achieve optimal efficiency in your cleaning processes while ensuring safety and reliability in your equipment choices!

Maintenance Tips for Longevity

To ensure your floor scrubber battery lasts as long as possible, consider the following maintenance tips:

Regular Charging:

Always charge your battery after use, even if it’s not fully depleted. This habit helps maintain battery health and performance. For instance, if you know your team will use the scrubber again within 24 hours, charging it immediately after use ensures it’s ready when needed.

Avoid Deep Discharges:

Try not to let your battery discharge completely before recharging. Deep discharges can significantly shorten the lifespan of your battery. Aim to recharge when the battery level drops to around 20%.

Clean Connections:

Keep the battery terminals clean and free from corrosion. Dirty connections can impede performance and lead to premature failure. A simple wipe with a cloth or using a wire brush on terminals can make a significant difference.

Temperature Control:

Store and operate your batteries within recommended temperature ranges to avoid damage. Extreme temperatures—both hot and cold—can adversely affect performance and lifespan.

Regular Inspections:

Schedule routine inspections of your batteries as part of your maintenance plan. Look for signs of wear, leaks, or swelling, which could indicate potential issues that need addressing before they become major problems.

Personal Experience

In my own experience with managing cleaning equipment, I’ve seen firsthand how the right battery choice can transform operations. When we switched from lead-acid to lithium-ion batteries in our floor scrubbers, we noticed a significant boost in productivity. The machines ran longer without needing a recharge, which meant less downtime and more thorough cleaning sessions.

Additionally, I remember a time when we neglected proper maintenance on our lead-acid batteries; it resulted in frequent replacements that ate into our budget. Learning from that experience taught me the importance of regular checks and proper charging habits.

One memorable incident involved an important client visit where we needed our floor scrubbers running at peak performance for an extensive cleaning session before their arrival. Thanks to our proactive approach in maintaining our lithium-ion batteries, we completed the job efficiently without any interruptions—a testament to how crucial proper battery management is!

Conclusion

Understanding floor scrubber batteries is not just about technical specifications; it’s about enhancing your cleaning efficiency and reducing costs in the long run. By choosing the right type of battery, maintaining it properly, and learning from personal experiences, you can ensure that your cleaning operations run smoothly and effectively.

As you consider your next steps, think about how investing time in understanding these batteries can lead to better performance in your cleaning tasks. I hope this article has provided valuable insights that resonate with you, making you feel more confident in managing your floor scrubber’s battery needs!

Call to Action

If you’re currently using floor scrubbers or planning to invest in new equipment, take some time to evaluate your current battery setup or consult with experts about which type would suit your needs best! Your choice today could save you time, money, and effort tomorrow!

6. Guide to find right scrubber replacement parts

When it comes to maintaining your cleaning equipment, finding the right spare parts for your scrubber is crucial. I know from experience how frustrating it can be to deal with a malfunctioning machine, especially when it disrupts your cleaning schedule. In this guide, I want to share my insights on how to find the right scrubber spare parts, ensuring that your equipment runs smoothly and efficiently.

Why It Matters

You might wonder why finding the right spare parts is so important. Well, let me tell you: using incorrect or low-quality parts can lead to more significant issues down the line, including costly repairs and downtime. I’ve been there—my team once used a generic part that seemed like a good deal at the time, only to face a breakdown just weeks later. The hassle of fixing that issue was not worth the initial savings.

The Benefits of Choosing the Right Parts

Enhanced Performance:

Using genuine or high-quality spare parts ensures that your scrubber operates at its best. This means cleaner floors and a more efficient cleaning process.

Longevity:

Quality parts can extend the life of your machine. I’ve seen machines last years longer simply because we invested in the right components from the start.

Cost-Effectiveness:

While it might be tempting to opt for cheaper options, investing in quality parts can save you money in the long run by reducing maintenance costs and avoiding premature replacements.

Improved Safety:

Faulty parts can pose safety risks to your employees and customers. Genuine parts are designed to meet strict safety standards, giving you peace of mind.

Warranty Compliance:

Using manufacturer-recommended parts ensures that you don’t void your machine’s warranty. This can save you a significant amount of money in the long run.

Common Wear Parts in Floor Scrubbers

Floor scrubbers have several components that are prone to wear and tear due to their constant contact with water, chemicals, and the floor surface. These parts typically need regular inspection and replacement to maintain optimal performance.

Some of the most common wear parts include:

Brushes and Pads:

These components come in direct contact with the floor, so they inevitably wear out faster than anything else on your machine. Brushes and pads should be inspected regularly for signs of wear, such as uneven bristles or damaged surfaces, and replaced as needed.

Squeegee Blades:

Squeegee blades are responsible for picking up water and debris from the floor. Over time, they can become worn, cracked, or misshapen, leading to poor water pickup and streaking. Regularly inspect the squeegee blades and replace them when necessary.

Filters:

Scrubbers typically have several filters, including solution filters, recovery tank filters, and vacuum filters. These filters can become clogged with debris, reducing water flow and suction power. Clean the filters regularly and replace them if they are damaged or excessively dirty.

Hoses and Fittings:

The hoses and fittings that connect the various components of the scrubber can become worn or damaged over time, leading to leaks and reduced water flow. Inspect these parts regularly and replace them if you notice any cracks, holes, or excessive wear.

Other Common Issues and Solutions

While wear parts are a common concern, scrubbers can also experience other issues that may require maintenance or repair.

Some of these include:

Battery Problems:

If your scrubber is battery-powered, issues with the battery, such as reduced runtime or failure to hold a charge, can cause significant problems. Ensure that the battery is properly maintained and replaced when necessary.

Electrical Issues:

Scrubbers have complex electrical systems that can malfunction due to loose connections, damaged wiring, or faulty components. If you experience issues with the scrubber’s electrical system, it’s best to have a qualified technician inspect and repair it.

Mechanical Issues:

Scrubbers have various mechanical components, such as motors, gearboxes, and wheels, that can wear out or become damaged over time. If you notice any unusual noises, vibrations, or performance issues, it’s important to have the machine inspected by a qualified technician.

How to Identify the Right Spare Parts

1. Know Your Machine

Before you start searching for spare parts, it’s essential to know your scrubber inside and out.

This includes:

Brand and Model:

Always check the brand and model number of your scrubber. This information is often found on a label located on the machine itself.

User Manual:

If you still have your user manual, it can be an invaluable resource for identifying the correct parts.

Serial Number:

The serial number is unique to each machine and can help you find the exact specifications of your scrubber.

2. Research Online

The internet is a treasure trove of information! Here’s how you can leverage it:

Manufacturer's Website:

Start by visiting the manufacturer’s website. They often have sections dedicated to spare parts where you can search by model number.

Online Retailers:

Websites like Amazon or specialized cleaning equipment retailers often carry a wide range of parts. Don’t forget to read reviews before making a purchase!

Industry Forums:

Join online forums and communities related to cleaning equipment. You can ask for recommendations and learn from the experiences of other users.

3. Consult with Experts

Sometimes, talking to someone with experience can save you a lot of time and hassle:

Customer Support:

Reach out to customer support from your scrubber’s manufacturer. They can guide you in finding the correct part.

Local Distributors:

If you have local distributors for cleaning equipment, they can be an excellent resource for both advice and availability.

Maintenance Technicians:

If you have in-house maintenance technicians or work with a service provider, they can provide valuable insights into the specific parts needed for your machine.

4. Consider Compatibility

When selecting spare parts, ensure they are compatible with your specific model. This is where I made my mistake before—I bought what I thought was a universal part only to find out it didn’t fit my machine properly. Always double-check compatibility!

Making Your Purchase

Once you’ve identified the right part, it’s time to make your purchase:

Compare Prices:

Don’t settle for the first price you see! Take some time to compare prices across different platforms.

Check Return Policies:

Make sure there’s a good return policy in case you end up with an incorrect part.

Consider Shipping Times:

If you need the part urgently, factor in shipping times when making your purchase. Some retailers offer expedited shipping options for an additional fee.

Look for Discounts:

Keep an eye out for sales, coupons, or bundle deals that can help you save money on your purchase.

Conclusion:

Your Cleaning Equipment Deserves It!

Finding the right spare parts for your scrubber doesn’t have to be a daunting task. By following these steps and keeping in mind my experiences, you’ll be well on your way to ensuring that your cleaning equipment remains in optimal condition.

Remember, investing in quality spare parts is investing in efficiency and longevity for your machines—and ultimately, that translates into better results for your cleaning tasks! So let’s keep those scrubbers running smoothly together! If you have any questions or need further assistance, feel free to reach out; I’m here to help!

7. Guide to importing floor scrubbers from China simple and stress-free

If you’re in the cleaning industry, you know that having the right equipment is essential for efficiency and effectiveness. One of the most critical pieces of equipment is the floor scrubber. However, importing these machines from China can seem daunting. I want to share my personal experiences and insights to help you navigate this process smoothly. By the end of this guide, you’ll feel empowered to make informed decisions about importing floor scrubbers, ensuring it’s a simple and stress-free experience.

Why Importing from China?

You might be asking yourself, “Why should I import floor scrubbers from China?” Here are a few compelling reasons:

Cost-Effectiveness:

Chinese manufacturers often offer competitive prices compared to local suppliers. I’ve saved a significant amount by sourcing directly from China, which allowed me to invest more in marketing and other essential areas of my business.

Variety of Options:

The range of models and features available from Chinese manufacturers is vast. Whether you need compact models for tight spaces or heavy-duty machines for large areas, you’ll find options that suit your needs perfectly.

Quality Manufacturing:

Many Chinese manufacturers adhere to international quality standards. I’ve personally visited several factories and was impressed by their commitment to quality control.

Current State of the Floor Scrubber Industry in China

The floor scrubber industry in China has experienced rapid growth in recent years. As of 2023, the market size reached approximately 122.1 billion yuan, reflecting a significant increase from previous years. This growth has led to a diverse landscape of suppliers ranging from high-end to budget-friendly options.

Characteristics of Different Supplier Tiers

High-End Suppliers:

Features:

These manufacturers often focus on advanced technology, durability, and superior cleaning performance.

Mid-Range Suppliers:

Features:

Mid-range suppliers balance quality and affordability, providing reliable machines with decent features.

Low-End Suppliers:

Features:

These suppliers often compete on price but may compromise on quality and durability.

Examples: Numerous smaller brands have emerged, providing basic models that meet minimal cleaning requirements.

How to Avoid Being Misled by Suppliers

With so many options available, it’s crucial to avoid potential pitfalls when selecting a supplier:

Do Thorough Research:

Look beyond just price; investigate the supplier’s reputation through reviews and ratings on platforms like Alibaba or industry forums.

Request References:

Ask potential suppliers for references from previous customers. Genuine suppliers should be willing to provide this information.

Inspect Samples:

Always request samples before making a bulk purchase. This allows you to evaluate the quality firsthand.

Understand Warranty Terms:

Ensure that the supplier offers a clear warranty policy that protects your investment against defects or issues.

Stay Informed About Market Trends:

Keep an eye on market trends and pricing fluctuations within the industry. This knowledge can help you negotiate better deals and avoid overpaying.

How to Calculate Total Costs When Importing from China

Understanding the total cost of importing floor scrubbers from China is crucial for effective budgeting and financial planning. Here’s how you can break it down:

1. Product Cost

This is the initial price of the floor scrubber as quoted by the supplier. Make sure this includes any customization or additional features you require.

2. Shipping Costs

Shipping costs can vary significantly based on the method chosen (air freight vs sea freight), weight, volume, and distance:

Air Freight:

Generally faster but more expensive; suitable for smaller shipments or urgent orders.

Sea Freight:

More economical for larger shipments but takes longer; ideal for bulk orders.

3. Insurance Costs

It’s wise to insure your shipment against loss or damage during transit. Insurance typically costs around 1-2% of the total value of your goods.

4. Customs Duties and Taxes

When your shipment arrives in your country, customs duties will apply based on the product’s value:

Import Duties:

These can vary by country but are usually calculated as a percentage of the product cost plus shipping.

Value Added Tax (VAT)

Value Added Tax (VAT) or other local taxes may also apply depending on your country’s regulations.

Example Calculation

Let’s say you’re importing 10 floor scrubbers at a cost of $3,000 each:

Product Cost = $30,000

Shipping Cost = $1,500 (for sea freight)

Insurance = $300 (1% of product cost)

Customs Duties = 10% (example rate) = $3,150

VAT = 15% (example rate) = $4,500

Total Cost Calculation:

Total Cost=Product Cost+Shipping Cost+Insurance+Customs Duties+VAT

Total Cost=30,000+1,500+300+3,150+4,500=$39,450

Step-by-Step Guide to Importing Floor Scrubbers

1. Research Manufacturers

Start by researching reputable manufacturers. Websites like Alibaba are great platforms to find suppliers. Look for those with good ratings and reviews. I remember spending hours browsing through profiles, but it was worth it when I found a supplier that matched my quality expectations and budget.

2. Explore Additional Supplier Channels

To expand your options for finding suppliers, consider these additional channels:

Trade Shows:

Attending trade shows such as the Canton Fair or Clean Show can be incredibly beneficial. These events allow you to meet manufacturers face-to-face, inspect products firsthand, and negotiate deals on-site. I’ve attended several trade shows in China, and the connections I’ve made there have been invaluable.

Industry Associations:

Joining associations related to cleaning equipment can provide access to exclusive supplier directories and networking opportunities. For example, organizations like ISSA (International Sanitary Supply Association) often have resources for connecting with manufacturers.

Social Media Groups:

Platforms like Facebook and LinkedIn host numerous groups dedicated to cleaning professionals and equipment suppliers. Engaging in these communities can lead to recommendations for reliable suppliers. I’ve found several trustworthy contacts through these groups who have helped me source equipment effectively.

Professional Networks:

Utilize platforms like LinkedIn to connect with industry professionals who may have insights into reputable manufacturers. Engaging with experts in the field can provide recommendations based on their experiences.

3. Request Quotes

Once you’ve identified potential suppliers, request quotes for the specific models you’re interested in. Be clear about your requirements, including quantity, specifications, and any certifications you may need. This step is crucial; I once overlooked it and ended up with a product that didn’t meet my standards.

4. Evaluate Samples

Before placing a large order, ask for samples. This allows you to assess the quality firsthand. I always recommend this step; it not only gives you peace of mind but also helps establish a relationship with the supplier.

5. Understand Import Regulations

Familiarize yourself with your country’s import regulations regarding cleaning equipment. This includes tariffs, taxes, and safety standards that must be met. I learned this the hard way when my first shipment faced delays due to missing paperwork.

6. Negotiate Terms

Once you’re satisfied with a supplier and their product, negotiate terms such as payment methods, delivery timelines, and warranties. Building a good rapport can lead to better deals in the long run.

7. Arrange Shipping

Decide whether you’ll handle shipping or if the supplier will manage it for you. Freight forwarders can simplify this process significantly by handling customs clearance and logistics.

8. Inspect Upon Arrival

When your shipment arrives, inspect the products immediately for any damage or discrepancies with your order. This step is vital; I once received a shipment with damaged units that could have been avoided with proper inspection.

Common Mistakes to Avoid

Overlooking Quality Checks:

Always prioritize quality over price; a cheaper machine may end up costing more in repairs.

Ignoring Warranty Information:

Ensure that the products come with a warranty to protect your investment.

Not Considering After-Sales Support:

Choose suppliers who offer reliable after-sales support for maintenance and spare parts.

Failing to Plan for Downtime:

Consider how long it will take for your machines to arrive and plan accordingly so your operations aren’t disrupted.

Conclusion:

Your Path to Success!

Importing floor scrubbers from China doesn’t have to be overwhelming if you approach it methodically. By following these steps and learning from my experiences, you can ensure that your import process is simple and stress-free.

Remember, investing time in research and building relationships with manufacturers will pay off in the long run—both in terms of cost savings and quality equipment for your business!

If you have any questions or need further guidance on importing floor scrubbers or calculating costs effectively, feel free to reach out; I’m here to help! Together, let’s make your cleaning operations more efficient than ever!

8. FAQ about Floor Scrubbers

1. What is a floor scrubber and how does it work?

A floor scrubber is an essential cleaning machine used to clean and maintain hard floor surfaces such as concrete, tile, vinyl, and even some types of hardwood floors. Unlike traditional mopping, which can leave behind dirt and moisture, a floor scrubber combines scrubbing, rinsing, and drying into one efficient process.

2. How It Works:

Dispensing Cleaning Solution:

The machine releases a cleaning solution onto the floor through a nozzle.

Scrubbing Action:

Rotating brushes or pads agitate the solution, breaking down dirt and grime effectively. The type of brush or pad used can vary depending on the floor type and level of soiling.

Vacuuming:

After scrubbing, the machine uses a vacuum system to suck up the dirty solution, leaving the floor clean and dry. This reduces slip hazards and enhances safety.

This process is much more efficient and effective than manual mopping, as the scrubber can clean large areas quickly and consistently.

2. What are the benefits of using a floor scrubber?

Using a floor scrubber offers numerous benefits for facility management and cleaning professionals:

Time Efficiency:

Floor scrubbers can clean large areas in a fraction of the time it would take to do so manually. For example, I once managed a facility where we switched from mopping to using a ride-on scrubber; our cleaning time was cut by over 50%.

Consistent Results:

Automated scrubbing ensures that every inch of the floor receives the same level of attention, leading to uniform cleanliness.

Labor Cost Reduction:

With less time spent cleaning, staff can focus on other important tasks. This not only saves money but also boosts employee morale by allowing them to engage in varied work.

Enhanced Hygiene:

The vacuuming feature removes dirty water from the surface immediately, reducing bacteria growth and improving overall hygiene—especially important in healthcare or food service environments.

Improved Floor Longevity:

Regularly using a scrubber helps maintain floors in better condition by preventing the buildup of dirt and grime that can cause wear over time.

3. What types of floor scrubbers are available?

There are several types of floor scrubbers available, each designed for specific applications and facility sizes:

Walk-behind Scrubbers:

Ideal for small to medium-sized areas, these scrubbers are maneuverable and easy to operate. They are perfect for retail spaces or office buildings where space is limited.

Ride-on Scrubbers:

Suitable for large areas and high-traffic environments like warehouses or shopping malls, ride-on scrubbers offer increased productivity as operators can cover more ground without fatigue.

Micro Scrubbers:

Perfect for cleaning tight spaces and hard-to-reach areas, micro scrubbers are compact and versatile. I’ve found them invaluable in areas like restrooms or narrow aisles where larger machines cannot fit.

Orbital Scrubbers:

Effective for cleaning and restoring floors, orbital scrubbers use a unique cleaning motion that can tackle stubborn dirt and stains without damaging the surface.

Automatic Scrubbers:

These advanced machines combine the power of a scrubber with automation features that allow them to navigate around obstacles. They are ideal for facilities with consistent cleaning needs where labor costs need to be minimized.

4. How do I choose the right floor scrubber for my facility?

When selecting a floor scrubber, it’s essential to consider your facility’s specific needs:

Size of Area:

Measure the total square footage you need to clean. For example, if you have an area larger than 20,000 square feet, a ride-on model may be more appropriate than a walk-behind model.

Type of Flooring:

Different surfaces may require specific brushes or pads. For instance, softer pads should be used on polished floors to avoid scratches.

Frequency of Cleaning: High-traffic areas may need more frequent cleaning; thus, investing in a durable machine designed for heavy use is wise.

Budget Considerations:

Consider both initial costs and ongoing maintenance expenses. Sometimes spending a little more upfront on high-quality equipment can save you money in repairs down the line.

Storage Space Availability:

Ensure you have enough room to store the scrubber when not in use; some models can be quite large.

Operator Experience Level:

Choose equipment that matches your staff’s skill level; simpler models may be better suited for less experienced operators.

5. How do I maintain my floor scrubber?

Proper maintenance is essential to ensure your floor scrubber operates efficiently:

Daily Cleaning:

After each use, wipe down the exterior and remove any debris from the brushes or pads. This simple step can significantly extend the life of your equipment.

Regular Inspections:

Check components such as hoses and squeegees for wear or damage regularly; this helps prevent costly repairs later on.

Brush Replacement:

Inspect brushes or pads after every 40 hours of use; replace them when they show signs of significant wear (e.g., fraying bristles).

Fluid Levels Maintenance:

Ensure solution tanks are filled with appropriate cleaning solutions before each use; monitor recovery tank levels during operation to prevent overflow.

Manufacturer Guidelines:

Follow the manufacturer’s recommended maintenance schedule closely; this often includes periodic professional servicing that can catch issues before they become serious.

6. What cleaning solutions should I use with my floor scrubber?

Always use cleaning solutions recommended by the manufacturer:

pH Level Compatibility: Choose solutions with pH levels appropriate for your flooring type—alkaline solutions work well on greasy surfaces while acidic solutions are better for mineral deposits.

Dilution Instructions:

Follow dilution instructions carefully; using too concentrated a solution can lead to residue buildup on floors.

Eco-Friendly Options:

Look for eco-friendly solutions that minimize environmental impact while still providing effective cleaning results—this is particularly important if you’re committed to sustainability practices.

Compatibility Checks:

Ensure that any new cleaning solution is compatible with your specific model; some machines may have restrictions based on their materials.

7. How can I ensure the safety of my employees when using a floor scrubber?

Prioritizing employee safety is essential when using a floor scrubber: