Keeping an industrial or commercial facility clean and safe for employees is a major concern for any business owner. So Industrial floor cleaning machines are shrewd purchases for any company with large floor spaces to clean: floor cleaning jobs that take several hours can be completed with the right floor cleaning machines in a small fraction of the time. But It is an important big investment, so the decision to purchase one should not be taken lightly, because the purchasing and maintenance costs might have a profound impact on the company’s Total Cost of Operations (TCO) in the long run.

This photo is from https://www.climet.com/tco.html

So For many business leaders tasked with a goal to reduce operating costs, it is critical to justify whether these expenses of purchasing industrial floor cleaning equipment are worth it or not.

“How to Justify Ownership Costs for Industrial Cleaning Equipment?” In this article, we will discuss below:

- How to calculate the Total Cost of Ownership (TCO)?

- What are other Factors to Consider for Purchasing Industrial Cleaning Equipment?

- Why is it Important to Invest in High-quality Cleaning Equipment?

- What Should You Know to Find High-quality Cleaning Equipment?

What is the Total Cost of Ownership (TCO)?

This photo is from https://www.linkedin.com/pulse/why-total-cost-ownership-critical-procurement-supply-b-eng-mba/

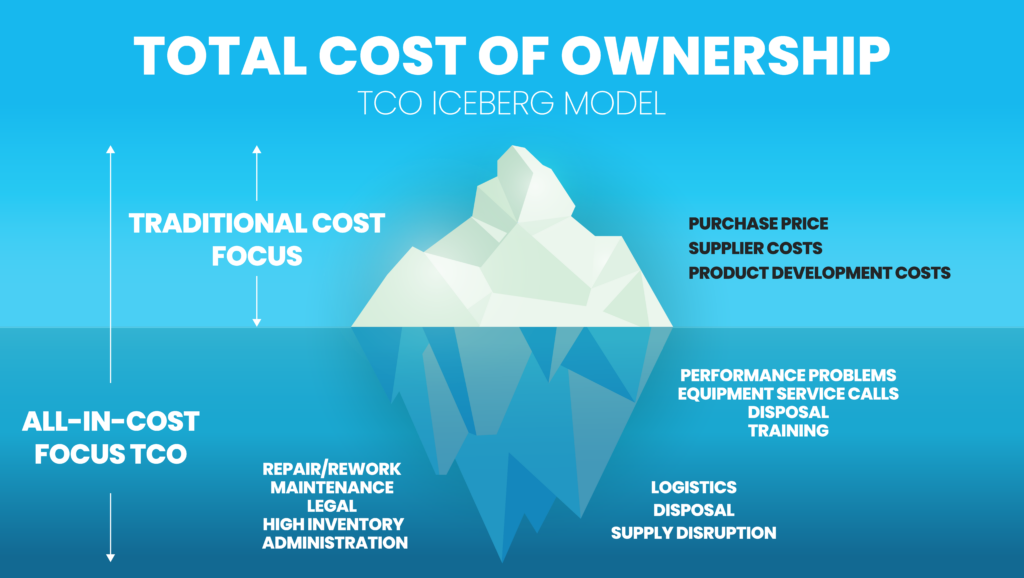

Before we dive into justifying the costs of ownership, it is important to first understand what exactly the “costs of ownership” entail. The total cost of ownership (TCO) is a term used to describe all expenses associated with owning and maintaining an asset over its lifetime.

Traditionally, facility management has focused on cleaning programs that obtain products at the lowest possible prices. The practice no longer aligns with a profitable TCO reduction strategy. This short-term view neglects the long-term costs that such products can entail.

When buying pricey equipment, many cleaning business owners focus on sticker prices. Or, they calculate labor savings from increased productivity and use that number to justify their purchase.

What too many overlook, however, is how much maintenance a machine will require over its lifetime. Burnishers, extractors, sweepers, scrubbers, and even certain vacuums can last fi ve to 10 or more years. That’s a lot of time for maintenance expenses to add up. And those costs can dramatically increase a machine’s total cost of ownership (TCO).

There are several factors that influence TCO (Total Cost of Ownership)

Consider the following costs and savings related to new equipment when you’re calculating TCO.

This photo is from https://optimas.com/blog/what-is-total-cost-of-ownership-and-why-is-it-important/

Costs:

1. Initial purchase price

Initial Expense: The price tag on the machine, plus accessories, taxes, shipping costs, and warranties.

Price Ranges for Scrubbers:

How Much Do Commercial Cleaning Machines Cost?

Commercial scrubbers vary in price from around $1,000 for basic models to over $20,000 for high-end, ride-on machines. The range reflects the diversity in scrubber efficiency and features tailored to different commercial cleaning needs.

- There are several types of small commercial floor cleaning machines including various vacuums and scrubbers that will be available for less than $1100.

- As you move towards walk-behind industrial scrubbers, the price will climb close to $5200.

- Ride-on scrubber machines start at around $10,400 for the smaller, entry-level units, but can range over $20,000 for a top-of-the-line unit that is well suited to maintaining the floors in very large industrial complexes.

Commercial Floor Cleaning Machines Sample Costs

Based on size, functionality, and additional features. Entry-level walk-behind models may start at a few thousand dollars, while high-end, ride-on sweepers can approach or exceed the cost of a new vehicle, depending on their capabilities.

Below are a few examples of prices for Commercial / Industrial Floor Cleaners which will give you an idea of how much you will pay for your purchase.

- $1,575 average cost for Manual Push Sweepers.

- $3,599 average cost of a walk-behind auto Floor cleaner.

- $6,200 to $20,000 Cost Ride-On Automatic Floor Cleaning Machines.

- Walk Behind Electric Floor Sweeper averages $3,600.

- Ride-on battery-powered outdoor floor cleaners average price $14,500.

| Manual Push Sweepers | $1575 |

| Walk-behind auto Floor cleaner | $3,599 |

| Ride-On Automatic Floor Cleaning Machines | $6,200 to over $20,000 |

| Walk Behind Electric Floor Sweeper | $3,600 |

| Ride-on battery-powered outdoor floor cleaners | $14,500 |

Consider other factors besides the purchase price

When justifying the purchase of new cleaning equipment, facility managers should consider more than just the purchase price, which means you should consider not just the upfront cost but also the long-term value. While these factors are essential, others should be considered to make a well-rounded decision. By looking at factors such as durability, efficiency, versatility, and safety features, facility managers can ensure that they make the best choice for their needs. Considering these factors can help avoid potential problems. Thoroughly research and compare different models to find the equipment that offers the best overall value and meets the facility’s specific requirements.

When evaluating scrubbers, pay attention to:

| Cleaning Path Width: | Wider paths cover more area, reducing labor time. |

| Solution Tank Capacity: | Larger tanks mean fewer refills, increasing productivity. |

| Battery Life: | Longer life equals less downtime, boosting efficiency. |

| Squeegee System: | A superior squeegee system ensures drier floors, reducing slip hazards. |

| Eco-Friendly Options: | Machines with reduced water and chemical usage have lower environmental impact. |

When evaluating industrial sweepers, pay attention to:

When considering the investment, sweeper longevity and operational efficiency are crucial factors. A well-built, durable sweeper may command a higher upfront cost but can offer a lower total cost of ownership over its lifespan.

- The efficiency of operation should also be a primary consideration. Machines that cover larger areas in less time and with less energy consumption provide greater value by reducing labor costs and minimizing downtime.

- It’s advisable to compare the lifespan of different models, warranty offerings, and the availability of replacement parts. A sweeper with a robust support network and accessible service can mitigate long-term costs associated with maintenance and repairs.

- Furthermore, consider the machine’s adaptability to different environments. Sweeper versatility can be a valuable asset that enhances its cost-effectiveness across various applications. Therefore, a comprehensive cost analysis should extend beyond the purchase price to encompass the sweeper’s performance and sustainability in your specific operational context.

2. Operating costs

- For not battery cleaning equipment, like Fuel cost etc.

- Training: The amount of money and/or lost time needed to get employees up to speed on the new machinery.

3. Maintenance and Repair Cost (Maintenance/replacement parts cost)

3-1 Don’t Skimp on Regular maintenance.

- Proper maintenance can help extend the lifespan of your equipment while preventing costly repairs or replacements. Be sure to follow recommended maintenance schedules and keep track of any potential

- To fully maximize your investment in machinery, routine maintenance is an absolute must. While vacuums and floor machines are more dependable and durable than ever, they still have moving parts and get a lot of use—and that inevitably causes problems.

- Proactive maintenance is crucial to minimize unexpected breakdowns which can be costly and disruptive to your operations.

3-2 Maintenance cost:

Maintenance costs include all the direct and indirect expenses of routine upkeep, repairs, replacement, and all maintenance activities that result from your efforts to keep physical assets in optimal working condition.

Some costs – like the sticker price for new equipment – are obvious. Others are hidden, often accumulating unnoticed.

3-3 Repairs Cost:

These are the unscheduled costs associated with servicing broken equipment (including things like shipping, rental costs, or added labor costs if the work must be done manually).

How to reduce Maintenance and Repair Expenses?

The cost of replacement parts for routine maintenance, plus the time required to keep the machine in good working order. That means in addition to the initial purchase price, you’re likely to encounter ongoing maintenance and repair expenses over the lifespan of your floor cleaning machine. These costs can accumulate and impact your budget if not managed wisely.

First, taking care of your machines daily will extend the amount of time between repair shop visits.

In fact, manufacturers say doing all planned maintenance can add about two years to the life of most floor machines.

Every machine is different and has its own unique maintenance requirements. To learn what the manufacturer recommends, you should often take time to communicate with the manufacturer or their agents. When bigger problems arise, their troubleshooting guide can help explain how to fix them (how to handle repairs in-house and when to seek help from a service professional).

Second, scheduled servicing, consistent cleaning, and proper operation are key to extending the life of your equipment. Here are some technical aspects you should consider to manage maintenance and repair expenses effectively:

- Regularly replace wear-and-tear items like brushes and filters to prevent larger issues.

- Ensure that batteries are properly maintained to extend their lifespan.

- Train your staff on the correct use of the machines to avoid operator error. It’s important to communicate to your staff why maintenance matters, plus share your expectations for their role in taking care of the machines. Make this a clear part of your employee training and daily task lists.

Third, keep an eye on the warranty period and consider warranty extensions for critical components.

The Importance of Investing in High-quality Cleaning Equipment

Here are a few frequently asked questions by our customers who are interested in our cleaning machines:

- Q: How often should I replace my Industrial Cleaning Equipment?

- A: The lifespan of industrial cleaning equipment varies depending on usage and maintenance. It is important to regularly assess the condition of your equipment and replace it when necessary to avoid costly breakdowns.

- Q: Is investment in Expensive Industrial Cleaning Equipment Worth it, or Should I choose Cheaper options?

- A: It ultimately depends on your specific needs and budget. While high-quality equipment may come at a higher upfront cost, it can result in long-term savings and benefits.

- While it may be tempting to choose cheaper, lower-quality cleaning equipment in order to cut costs, this can actually cost you more in the long run. Low-quality equipment may require frequent repairs or replacements, leading to higher overall costs and potential downtime for your facility.

- Investing in high-quality industrial cleaning equipment may come with a higher upfront cost, but it can save you money in the long run by reducing maintenance and replacement expenses. Additionally, high-quality equipment often comes with better warranties and customer support, providing added value for your investment.

Additionally, well-maintained equipment is less likely to break down or require repairs, minimizing downtime and potential operational disruption.

Consider the case of floor scrubbers. The upfront cost of these machines can range from $20,000 for ride-on models to more than $80,000 for advanced, automated, robotic models. If you’re able to extend the lifespan of your current equipment, then it gives the business time to wait for the market to dictate more affordable prices as technology advances. This advantage allows businesses the ability to reserve capital for a longer period, while competitors spend higher amounts at the cost of being early adopters. Even if upgrades are necessary, imagine the cost-saving potential of extending the usable life of such a substantial investment by even 10 or 20 percent. The savings are not merely substantial – they’re transformative.

Savings :

Saving from Labor/productivity

Labor Costs: Streamlining For Efficiency & Savings

- Labor represents the most substantial chunk of cleaning and maintenance expenditures for most businesses. Maintenance labor costs account for 90% of the overall cleaning expenses, according to industry estimates. Labor cost underscores the critical role that labor efficiency plays in your Total Cost of Operations and the vast potential for savings on labor expenses.

- Every new maintenance employee or contractor brought on board requires training in the use of cleaning products and equipment. By using superior cleaning products that require fewer reapplications and reduce equipment wear and tear, you can decrease the frequency and cost of training.

Saving from Potential for cost savings:

In the long run, investing in quality industrial cleaning equipment may save money by reducing labor costs, minimizing downtime, and preventing costly accidents or damage to equipment and facilities.

Saing from Lifespan of equipment ( Longer lifespan and cost-saving! )

High-quality equipment is designed to last longer and require less frequent repairs or replacements. This can lead to significant cost savings over time, as well as reduced downtime for your facility.

Saving from less water and detergent usage

Saving from longer life of flooring

Saving from accident reduction

What Should You Know to Find High-quality Cleaning Equipment?

First, get clear about a machine’s expected life span.

Second, ask your supplier to outline the routine maintenance requirements for every machine you’re considering:

- How often will you need to replace parts due to normal wear and tear?

- How much do these items cost?

- Can you fix these in-house or do you need to send the equipment out?

- How much downtime is required?

- How do these variables change from machine to machine?

- What other parts are likely to need replacement over that time, and what are those costs?

As an example, vacuums will routinely need replacement brushes, pads, pad drivers, wheels, rubber skirts, dust control devices, filters, casters and hoses. Over a 7 to 10-year lifespan, however, it may also eventually need new brush motors, drive motors, control boards, batteries, electrical cords, hose connectors, switches, solenoids, regulators, and more.

Finally, ask about common repair issues.

You may want to seek input from peers or look at online reviews to get unbiased information. Learn what is and isn’t covered in any warranty offered by the manufacturer.

As an example, many machines come with 1 to 3-year warranties that cover repairs (not routine maintenance). Often, these warranties cover the costs of parts during that period, but may only cover labor costs for the first year.

After finishing the above homework, with all of this information in hand, you’ll be a more savvy shopper to calculate purchase price, maintenance costs, and labor savings for each product, so you can compare apples to apples.

You may be surprised to find that a more expensive machine will actually cost far less over its lifetime than a discount product.

Note: If you’re buying equipment exclusively for a single client and expect to only need that machine for that contract period, price may actually be the most important factor. Also, rental equipment may be worth considering in these cases.

Conclusion:

For any cleaning operation, good cleaning equipment is an important part of improving productivity and boosting the bottom line.

However, before rushing to purchase a pricey floor-care machine, you should understand TCO and the role maintenance plays in the short- and long-term costs of any machine.

For industrial cleaning equipment, this includes not only the initial purchase price but also ongoing costs such as maintenance, repairs, and replacements. It is essential to consider these additional expenses when justifying the costs of ownership for industrial cleaning equipment.

It is important to Invest in High-quality Cleaning Equipment, You may be surprised to find that a more expensive machine will actually cost far less over its lifetime than a discount product.