How Floor Cleaning Machine Manufacturers Ensure Top-Quality Equipment

Key Quality Standards Trusted by Top Floor Cleaning Machine Manufacturers

From Factory to Floor: How Floor Cleaning Machine Manufacturers Ensure Quality

Behind the Scenes: Quality Control Processes in Floor Cleaning Machine Manufacturing

If you’re searching for a reliable floor cleaning machine manufacturer, you’re not just looking for a piece of equipment. You’re looking for trust, performance, and consistency. I know this because, at CY Cleaning Equipment, we’ve been in your shoes. We understand what it’s like to depend on machines to do the hard work and make your business shine (literally). Whether you’re a cleaning contractor, a facility manager, or a procurement head, the quality of the machines you invest in matters more than you may realize.

Let me walk you through what happens behind the scenes—from the factory floor to your facility’s floor—and how we ensure that every scrubber, sweeper, or vacuum meets the highest standards.

It All Starts With Materials: The First Gate of Quality

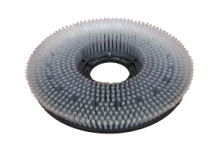

When we talk about floor cleaning equipment factory quality control, it starts way before the first screw is turned. Every component we use—from the motors to the squeegees—is rigorously vetted.

Incoming Material Inspection

Our quality journey begins the moment materials arrive at our factory. Each batch goes through:

- Visual checks to identify any obvious damage or discrepancies.

- Dimensional checks using precision instruments to ensure parts meet strict specifications.

- Material certifications provided by suppliers, which we verify with third-party labs if needed.

This is crucial. A bad component in a floor scrubber could mean downtime in your operations, and that’s not something we’re willing to risk.

Production with Purpose: Built with Care, Not Just Speed

When production begins, it’s not just about assembling parts. Every team member knows that they’re building machines that will clean hospitals, schools, factories—places where cleanliness isn’t a luxury, it’s a necessity.

In-Process Quality Control

Our assembly lines are designed to make quality checks second nature:

- Checklists at every station, so no step is skipped.

- Torque settings verified for every bolt—yes, every single one.

- Functionality tests after each critical assembly step.

I’ve seen firsthand how our team takes pride in their work. You can feel it in the way they pause to double-check alignment or how they flag even a minor defect.

Real-World Simulation: Our Favorite Part of the Process

Once a machine is fully assembled, we don’t just box it up and ship it out. No way. We test every machine in conditions that mimic real-world environments.

Final Product Testing

This includes:

- Power-on inspections for motors, controls, and safety switches.

- Water flow tests to check pressure, consistency, and leak-proof performance.

- Scrubbing simulation on factory floors with various surfaces (smooth, tile, concrete).

- Noise level measurements, because we know you don’t want disruptive equipment.

Every machine passes through our quality control chamber, where it’s subjected to a 30-minute operational stress test. Only if it performs flawlessly does it move to packaging.

Packaging with Integrity

You might not think packaging has anything to do with quality, but we’ve learned otherwise. Proper packing protects your investment. That’s why we use:

- Shock-resistant foam linings

- Moisture-proof wraps

- Durable pallets rated for long-distance travel

This attention to detail reduces shipping damage and ensures that when your machine arrives, it’s in the exact condition we sent it.

Continuous Improvement: Listening and Learning

We don’t stop after the sale. We follow up. We ask for feedback. We monitor performance. If you’ve bought from CY Cleaning Equipment, you’ve probably received one of our check-in calls or surveys.

Your insights fuel our R&D. A comment about brush longevity might inspire a new material trial. A complaint about a handle design might lead to an ergonomic redesign. This loop helps us stay ahead in a competitive industry.

Why This Matters to You

Choosing the right floor cleaning machine manufacturer isn’t just about price or specs—it’s about peace of mind. When you buy from a company that takes floor cleaning equipment factory quality control seriously, you’re making a long-term investment in efficiency, safety, and reliability.

At CY Cleaning Equipment, we don’t just build machines. We build partnerships, grounded in our commitment to quality from the first material inspection to the final sweep across your floor.

So next time you see a shiny, perfectly clean floor, know that there’s a story behind it. A story of people who care, processes that work, and quality that lasts.

Want to know more about how we build our machines or see a demo? Just visit www.cleaningbling.com or drop me a message. I’d love to show you around our factory—virtually or in person.

Let’s make your floors shine—with confidence.

Need Help? Contact Us Now!

Looking for top-quality scrubbers and sweepers for industrial & commercial use from Chinese Leading manufacturer?

Talk about your needs.